Your Plastic Thermoforming & Injection Wizards.

We specialize in the design and manufacture of sustainable plastic molds, components, and casings for a wide range of industries — delivering quality and reliability since 2001.

Plastic Thermoforming & Injection In Action!

Take a 360-degree virtual tour of our cutting-edge plastic factory in Thailand. See our state-of-the-art equipment and skilled workforce in action. Discover how Alcami delivers exceptional plastic thermoforming & Injection Molding solutions to meet your business needs.

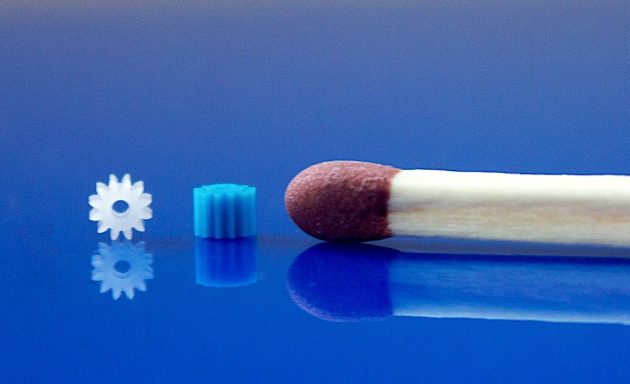

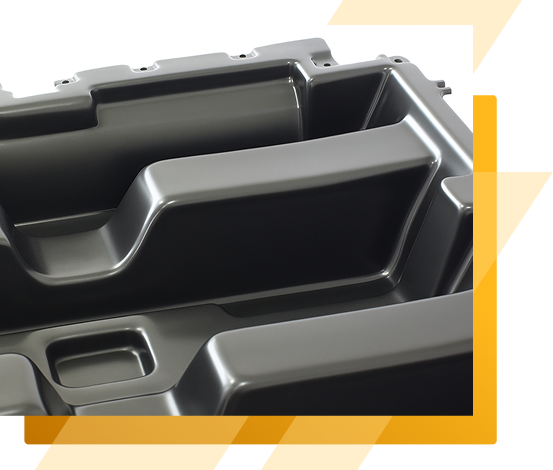

Automation Tray

One of our customers has been investing in automation equipment to automate their production line. This automation will increase their output with 20%, using less operators.

Scraperite

Established and patented in 2004, the Scraperite brand is a line of plastic razor blades and holders developed for cleaning and scraping on surfaces where metal scrapers and blades would cause damage.

All Our Solutions

A vertically integrated turnkey solution that reduces the need to deal with multiple suppliers. Read More

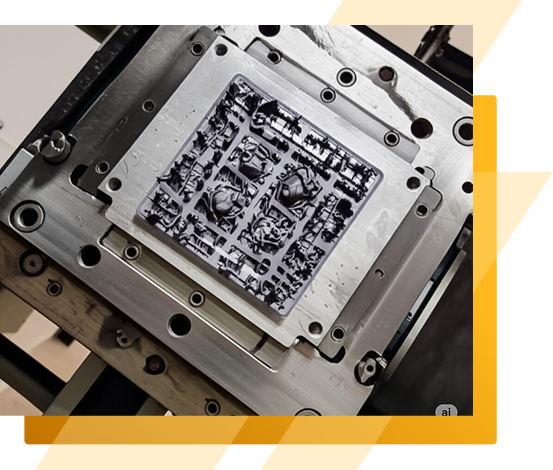

Plastic Thermoforming

Plastic thermoforming is a well-known manufacturing process that involves heating a sheet of material so it can be stretched over a mold to attain a desired part shape.

“Alcami is an excellent, highly professional manufacturer for our quality plastic parts.”

Noah Shepherd, Director – Advanced Manufacturing Director, Asia-Pacific. StanlyBlack&Decker

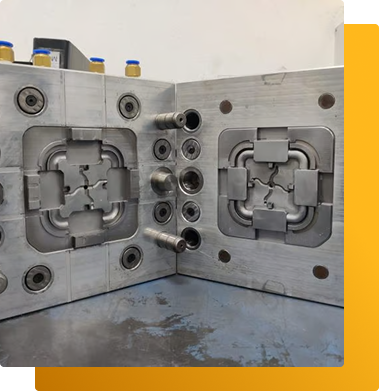

Plastic Injection Molding

“Working with Alcami is a smooth experience — from engineering & design, through to molding & mass production…”

Claire Souchet, Regional Director at LR Paris

All Our Facilities

The Alcami group has several facilities in Thailand, including manufacturing and packaging locations. Read More

Scraperite

Established and patented in 2004, the Scraperite brand is a line of plastic razor blades and holders developed for cleaning and scraping on surfaces where metal scrapers and blades would cause damage.

Automation Tray

One of our customers has been investing in equipment to automate their production line. This automation will increase their output by 20%, using less operators.

Latest News