Automation Tray

One of our customers has been investing in automation equipment to automate their production line. This automation will increase their output with 20%, using less operators.

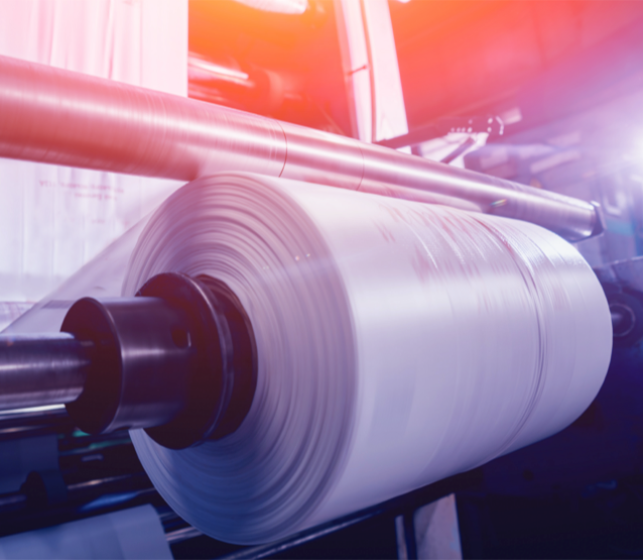

Plastic film conversion is the process of precision cutting a sheet of plastic film to varying lengths and widths for use in other manufacturing processes. This technique is used to create a wide variety of parts, fabricate insulators and components for electronics and medical equipment.

At Alcami we advise you through every step of your manufacturing process, including post-production services like plastic film conversion.

Alcami specialises in a variety of post-production film conversion services. We begin with a purchased or extruded material sheet and use slitting processes to cut it to the correct length and width for the desired application. After this we are able to punch out parts, which can then be bent or taped with double-sided adhesive stickers.

If you need to meet additional conversion requirements, please reach out to us and we will be happy to discuss how we can cater to your specific project needs.

Quality Assurance

Whatever your production or post-production needs, you can be confident that Alcami will handle your project with expertise and precision. We strive to help you meet all your project specifications and ensure you the highest possible quality for all your products.

Project Efficiency

Alcami’s vertical integration of planning, production and post-production services, allow us to move seamlessly through all stages of your project. Our services can be carried out with maximum efficiency to make sure you receive a high quality product in a timely manner.

Convenience

Not only does Alcami’s turnkey solution to your manufacturing needs ensure high quality, efficient work, but it alleviates the stress of dealing with multiple suppliers. Our customer-centered approach prioritizes client needs making it easy for you to see your project through with satisfaction.

Contact us to learn more about our specific capabilities and recommendations for how our cleaning solutions can be suited to your needs and your project specifications.

Allow us to use our in-house plastic film conversion services to help you tackle any post-production requirements your project may have.

We have several types of conversion processes:

Yes, we can provide both heat and ultrasonic welding.

Yes, in that case we will first thermoform the parts, and then we will do the 3-D cutting in a separate operation.

The Alcami group has several facilities in Thailand, including manufacturing and packaging locations.

The Alcami group has several facilities in Thailand, including manufacturing and packaging locations.

Explore our latest news, research, and insights.

One of our customers has been investing in automation equipment to automate their production line. This automation will increase their output with 20%, using less operators.

One of our customers is a multinational company which is in white goods, meaning washing machines, refrigerators, ovens, stoves, etc.

Established and patented in 2004, the Scraperite brand is a line of plastic razor blades and holders developed for cleaning and scraping on surfaces where metal scrapers and blades would cause damage.

One of our customers has been investing in automation equipment to automate their production line. This automation will increase their output with 20%, using less operators.

One of our customers is a multinational company which is in white goods, meaning washing machines, refrigerators, ovens, stoves, etc.

Established and patented in 2004, the Scraperite brand is a line of plastic razor blades and holders developed for cleaning and scraping on surfaces where metal scrapers and blades would cause damage.

Alcami combines different production technologies allowing us to provide a turnkey solution for a variety of parts. We combine this with sourcing and logistics services, so our customers don’t need to worry about shipping and storage.

Alcami combines different production technologies allowing us to provide a turnkey solution for a variety of parts. We combine this with sourcing and logistics services, so our customers don’t need to worry about shipping and storage. Let us help you find the perfect solution for your company. Fill out the form below to get in touch with us.

Your Plastic Thermoforming & Injection Wizards.

Design & manufacture of sustainable plastic molds, parts, & casings since 2001.