Automation Tray

One of our customers has been investing in automation equipment to automate their production line. This automation will increase their output with 20%, using less operators.

At Alcami Global, we specialize in delivering top-tier plastic molding solutions tailored to your manufacturing needs. We specialize in mold fabrication for plastic injection molding and plastic thermoforming..

With an in-house team of skilled product and mold engineers, we are committed to guiding you through every step of your project, ensuring exceptional quality and precision.

Alcami Global provides plastic injection molding and thermoforming services for industries such as automotive, electronics, and consumer goods..Our process includes mold design, fabrication, and production using advanced CAD/CAM systems and CNC machining. We offer solutions for high-strength, lightweight, and intricate plastic components tailored to specific project requirements.

Our in-house team ensures efficient mold development, minimizing lead times and production costs. With capabilities for both low- and high-volume manufacturing, we deliver consistent, precise results. Whether optimizing existing designs or creating new molds, our engineers prioritize performance, durability, and efficiency in every project.

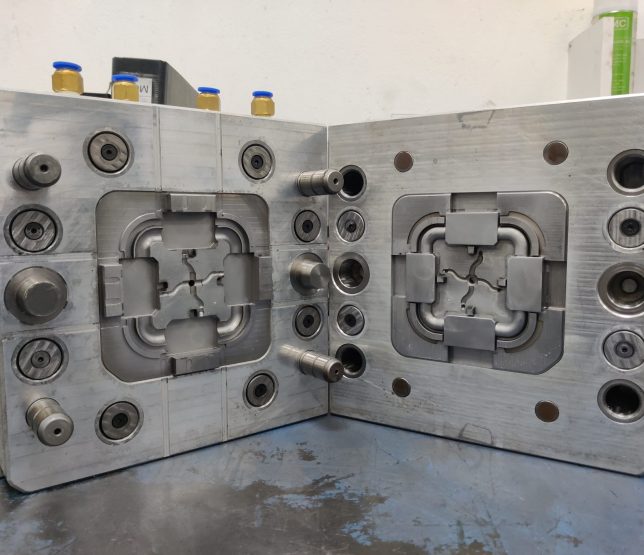

The foundation of any successful plastic molding project is a well-crafted mold. At Alcami, we use advanced machining techniques and durable materials such as hardened steel, pre-hardened steel, aluminum, and other high-strength alloys to create molds built for performance. Our state-of-the-art processing, utilizes CAD/CAM systems and CNC machines to guarantee precision and reliability.

With flexible machining options and a creative problem-solving approach, Alcami is equipped to handle even the most complex mold fabrication projects efficiently.

Whether you need expert guidance on mold design, precision machining, or full-scale production, Alcami Global is here to support your success. Contact our engineering team today for tailored recommendations and collaborative solutions that bring your plastic molding vision to life.

Reach out now to start your journey with industry-leading plastic molding solutions!

Allow us to help you tackle any mould fabrication project with precision, creativity and competitive pricing.

At Alcami we advise you through every step of your manufacturing process, including pre-production product design and mold fabrication. Our in-house mold engineers work directly with our manufacturing floor team to ensure efficiency and precision throughout the process.

If you choose Alcami to bring your mold designs to life, our engineering team will provide you with expert consultation catered to your specific project needs.

Alcami specializes in the design and machining of molds used in the many manufacturing processes available at our locations:

Alcami’s expert engineering team is skilled in finding creative solutions for any manufacturing challenge. A variety of machining methods are used to create the ideal molds for a diverse range of design requirements.

Contact us to discuss how the Alcami team can address your mold and product design needs.

The Alcami group has several facilities in Thailand, including manufacturing and packaging locations.

The Alcami group has several facilities in Thailand, including manufacturing and packaging locations.

Explore our latest news, research, and insights.

One of our customers has been investing in automation equipment to automate their production line. This automation will increase their output with 20%, using less operators.

One of our customers is a multinational company which is in white goods, meaning washing machines, refrigerators, ovens, stoves, etc.

Established and patented in 2004, the Scraperite brand is a line of plastic razor blades and holders developed for cleaning and scraping on surfaces where metal scrapers and blades would cause damage.

One of our customers has been investing in automation equipment to automate their production line. This automation will increase their output with 20%, using less operators.

One of our customers is a multinational company which is in white goods, meaning washing machines, refrigerators, ovens, stoves, etc.

Established and patented in 2004, the Scraperite brand is a line of plastic razor blades and holders developed for cleaning and scraping on surfaces where metal scrapers and blades would cause damage.

Alcami combines different production technologies allowing us to provide a turnkey solution for a variety of parts. We combine this with sourcing and logistics services, so our customers don’t need to worry about shipping and storage.