Alcami Technology (Thailand) Co., Ltd.

Our Prachinburi factory is located in Industrial Park 304, and houses Alcami Manufacturing and Alcami Technology. We have about 10,000 m2 of factory floor, with approximately 200 people working here. The building sits on a plot of 22,500 m2, ready for expansion. Check out our factory virtual tour, and contact us for more details.

Address

693 Moo 10 Tha-Tum, Srimahaphote 25140 Pachinburi, Thailand

Contact

Tel: +66 37 210495, Fax: +66 37 210496

Email: [email protected]

Website

Get in touch

No matter what your manufacturing project, Alacami is here to help. We have an in-house team of design engineers and incorporated post-production services to help us run your project smoothly from start to finish. Contact us today to learn more about what we can do for you.

FAQ

Which companies are based here?

Alcami Manufacturing and Alcami Technology are based in Prachinburi

Which service are provided here?

In Prachinburi we do thermoformong, injection moulding, DI washing, and CNC machining

Nulla bibendum, leo ac placerat aliquam, elit ex sagittis urna, eu mattis velit dui ut sapien. Nullam et ligula nec orci elementum pellentesque.

Nulla bibendum, leo ac placerat aliquam, elit ex sagittis urna, eu mattis velit dui ut sapien. Nullam et ligula nec orci elementum pellentesque.

Nulla bibendum, leo ac placerat aliquam, elit ex sagittis urna, eu mattis velit dui ut sapien. Nullam et ligula nec orci elementum pellentesque.

Solutions Offered

No matter what your manufacturing project, Alacami is here to help. We have an in-house team of design engineers and incorporated post production services to help us run your project smoothly from start to finish.

Solutions Offered

No matter what your manufacturing project, Alacami is here to help. We have an in-house team of design engineers and incorporated post production services to help us run your project smoothly from start to finish.

Learn about Alcami’s thin and thick gauge thermoforming processes and how we can help you to create a variety of high-precision parts.

Alcami’s plastic film conversion capabilities allow us to precision cut plastic film to varying lengths and create a wide range of parts, fabricate insulators and components for electronics or medical equipment.

At Alcami, we are able to offer testing throughout and following the production process and provide post-production assembly to ensure the highest quality final products for all our customers.

Alcami’s CNC machining capabilities allow us to create precision parts with high accuracy and tight tolerances, in addition to creating moulds or prototypes to meet all of our client’s needs.

DI washing is just one of Alcami’s high-quality post-production services, done in a class 100 cleanroom to help our customers meet all their necessary cleanliness requirements.

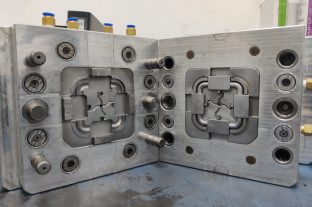

Injection moulding is one of the cornerstones of Alcami’s manufacturing arsenal that we use to provide our customers with high-quality, strong, replicable parts.

Alcami offers in-house mould fabrication services to give our customers a turnkey solution for all of their production needs.

Alcami’s sheet extrusion services are an essential part of getting the precise material thickness needed for our thermoforming projects, ensuring the highest quality for all our products.

The Alcami group includes a team of experienced, multilingual specialists to assist in sourcing commodities and customized items from around the globe.

Alcami has its own transportation company to handle any of our customers’ inbound and outbound domestic shipping needs with ease.

When your project is completed, Alcami has several warehouses where we can assist you with receiving, storing, and delivering your products.

Get in Touch - We Can Help

Alcami combines different production technologies allowing us to provide a turnkey solution for a variety of parts. We combine this with sourcing and logistics services, so our customers don’t need to worry about shipping and storage.